Madhya Pradesh, a state with a rich agricultural heritage and a vibrant poultry industry, offers a wealth of opportunities for entrepreneurs venturing into the promising realm of poultry processing. With a thriving poultry sector and a growing demand for processed poultry products both domestically and internationally, establishing a poultry processing plant in this region can be a venture with immense potential.

Demand Devouring Distance:

India is the world's third-largest producer of poultry meat, and Madhya Pradesh stands as a significant contributor to this impressive output. This abundance of raw material fuels a thriving market for processed poultry products, ranging from simple cooked chicken to value-added items like chicken nuggets, sausages, and ready-to-eat meals. The growing health consciousness among consumers has also led to a demand for functional poultry products, such as low-fat and high-protein options.

Raw Material Availability and Sources:

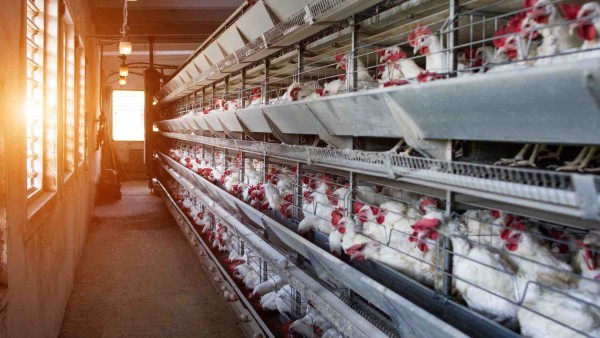

Madhya Pradesh boasts a robust poultry infrastructure, with a network of over 10 million poultry birds, including broilers, hens, and ducks. Sourcing fresh poultry from these farms is relatively straightforward and can be achieved through direct partnerships with farmers or through aggregators.

Processing Techniques:

A poultry processing plant typically involves a series of steps to ensure the safety, quality, and preservation of the poultry. These steps include:

-

Receipt and Inspection: Poultry is received from farms and inspected for quality and freshness.

-

Slaughtering: Poultry is humanely slaughtered and inspected for any signs of disease or contamination.

-

Defeathering: Feathers are removed from the poultry, typically through a process called plucking or defeathering.

-

Evisceration: The poultry is eviscerated, removing the internal organs and intestines.

-

Cutting and Packing: The poultry is cut into various cuts and sizes according to market demand and packaged in sterile containers.

Machinery Requirements:

A poultry processing plant requires a range of machinery to handle the various stages of poultry processing. These include:

-

Slaughtering equipment: To humanely slaughter and process poultry.

-

Defeathering equipment: To remove feathers from poultry.

-

Evisceration equipment: To remove internal organs from poultry.

-

Cutting equipment: To cut poultry into various cuts and sizes.

-

Packaging machines: To pack poultry in sterile containers.

By-Products:

Poultry processing generates valuable by-products that can be further processed or used as animal feed. These include:

-

Feathers: Used in pillows, comforters, and insulation.

-

Organs: Used in pet food and animal feed.

-

Blood: Used in blood sausages and other processed poultry products.

Value-Added Products:

To stand out in the market, poultry processing plants can produce value-added products, such as:

-

Chicken nuggets: Breaded and fried chicken pieces.

-

Chicken sausages: A variety of sausages, ranging from chicken sausages to turkey sausages.

-

Ready-to-eat meals: Packaged meals with poultry as the primary ingredient.

-

Functional poultry products: Poultry fortified with nutrients like omega-3 fatty acids or protein.

Preservation Methods:

Processed poultry products can be preserved using various methods, including:

-

Refrigeration: For short-term storage.

-

Freezing: For longer-term storage.

-

Canning: For the longest shelf life.

Nutritional Value:

Poultry is a valuable source of protein, niacin, vitamin B6, phosphorus, and selenium. Processed poultry products retain most of these nutrients, making them a nutritious addition to a balanced diet.

Packaging:

Proper packaging is crucial for preserving the quality and safety of poultry products. Common packaging materials include:

-

Vacuum-sealed packages: For long-term storage.

-

Canned products: For the longest shelf life.

-

Frozen products: For extended shelf life.

Market Demand:

The domestic market for processed poultry products is large and growing, driven by increasing disposable incomes, urbanization, and a preference for convenient and ready-to-eat meals. Additionally, there is a strong export market for Indian poultry products, particularly in Southeast Asia, the Middle East, and Africa.

Certifications:

To ensure food safety and quality, poultry processing plants must obtain appropriate certifications from the Food Safety and Standards Authority of India (FSSAI).