In India state like Madhya Pradesh, with its fertile land and abundant sunshine, offers the perfect environment for cultivating tomatoes. But what happens to these delicious fruits after harvest? Enter the world of tomato processing, a lucrative and impactful venture with immense potential in the state. Tomato Processing units can help you in become a successeful entrepreneur, but also it will help local farmers.

Demand for Processed Tomato Products:

The Indian market for processed tomato products like ketchup, puree, sauces, and juices is booming, driven by rising disposable incomes, urbanization, and changing dietary habits. This demand is expected to reach USD 1.4 billion by 2024, presenting a golden opportunity for entrepreneurs. Above this the dependence of tomato processors on established brands has reduced due to advent of e-commerce.

Raw Material Availability:

Madhya Pradesh is a major tomato producer, with over 26 lakh metric tons grown annually. This abundant raw material, readily available from farmers' cooperatives and mandis, ensures a stable supply chain.

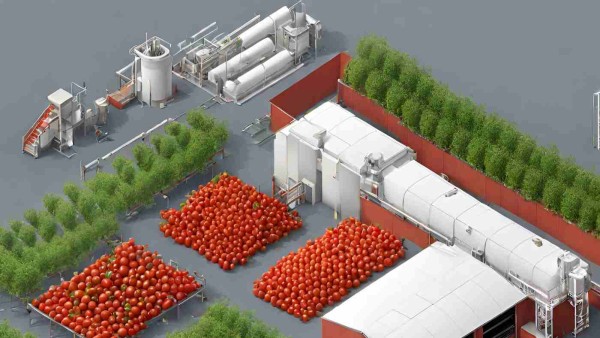

Processing Techniques:

Tomato processing involves various techniques like washing, sorting, peeling, pulping, concentrating, and packaging. Depending on your target products, you can choose from a range of machinery, including:

- Washing and sorting lines: These remove impurities and ensure uniform quality.

- Pulping machines: These extract juice and separate pulp from skin and seeds.

- Evaporators and concentrators: These reduce water content to produce tomato paste or puree.

- Aseptic filling machines: These ensure product sterility and extended shelf life.

By-products and Value-added Products:

Don't let anything go to waste! Tomato peels and seeds can be converted into valuable by-products like animal feed, cosmetics, and pharmaceuticals. Additionally, consider producing value-added products like sun-dried tomatoes, tomato powder, and flavored sauces to diversify your offerings.

Preservation Methods:

Maintaining product quality is crucial. Employ methods like refrigeration, heat sterilization, and aseptic packaging to extend shelf life and prevent spoilage.

Nutritional Value:

Tomatoes are rich in vitamins A, C, and potassium, making them a healthy addition to any diet. Promote this nutritional value to attract health-conscious consumers.

Packaging Methods:

Attractive and functional packaging is essential for brand recognition and product protection. Choose materials like glass, PET bottles, or tetra packs based on your target market and product type.

Domestic and International Demand:

The domestic market for processed tomatoes is vast, but don't stop there. Explore export potential in the Gulf, European, US, and Japanese markets, each with specific requirements and preferences.

Certifications:

To comply with domestic regulations, obtain FSSAI certification and HACCP implementation for food safety. For export, additional certifications like BRC or IFS might be necessary.

E-commerce Potential:

Tap into the growing online market by setting up an e-commerce platform for direct sales and brand building.

Plant Cost in Madhya Pradesh:

The cost of setting up a tomato processing plant in Madhya Pradesh can vary depending on the scale of operation, technology used, and desired processing capacity. Expect an initial investment of INR 10 lacs to INR 5 crore for a small-scale plant.

Machinery Suppliers:

Several Indian and international companies supply tomato processing machinery. Some notable names include:

-

Anjoplus Machines:

- Website: http://www.fruitprocessing.co.in/

- Email: info@fruitprocessing.co.in

- Phone: +91-251-234-1234

-

RAMAN INDUSTRIES:

- Website: http://ramanindus.com/

- Email: sales@ramanindus.com

- Phone: +91-80-3740-2796

-

SHIVA ENGINEERS:

- Website: http://www.shivaengineers.in/

- Email: sales@shivaengineers.in

- Phone: +91-20-27129610, +91-20-27127104

-

Process Masters Equipment (I) Pvt. Ltd.:

- Website: http://www.process-masters.com/

- Email: info@process-masters.com

- Phone: +91-20-27654321

-

Zigma Machinery & Equipments Solutions:

- Website: https://www.zigmainternational.in/

- Email: sales@zigmainternational.in

- Phone: +91-984-321-0098

Government Subsidies:

The Madhya Pradesh government offers various incentives for agro-processing industries, including subsidies on land, infrastructure, and machinery. Explore schemes like the MP Food Processing Policy and the Mukhyamantri Krishi Yojana for potential financial support.

Starting a tomato processing plant in Madhya Pradesh is a promising venture with immense potential for growth and profitability. By understanding the market demand, utilizing local resources, and employing innovative techniques, you can contribute to value addition in the agricultural sector while tapping into a lucrative business opportunity.

Remember, thorough market research, financial planning, and obtaining necessary licenses and certifications are crucial for success. With careful planning and execution, your tomato processing plant can be a thriving contributor to Madhya Pradesh's agricultural landscape and your own entrepreneurial journey.